|

|

|

|

News The Project Technology RoboSpatium Contribute Subject index Download Responses Games Gadgets Contact <<< Extruder V6.1 + V6.2 Lunar eclipse 2015 >>> Syringe ExtruderThe video on the Syringe Extruder.Extruder Details

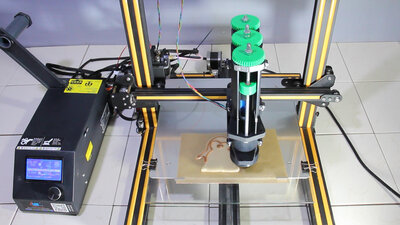

In the comments on my sugar experiment with my direct granulates extruder, many suggestions for printable recipes were made that could be worth trying out. Many of them result in pasty materials such as fruit gums or caramel candies, which are difficult to process in an extruder designed for granules. With the syringe system, the variety of printable materials can be expanded. A source of inspiration was the "Universal Paste Extruder", an open source project from Richard Horne. The printer I am using is a Creality CR10S.

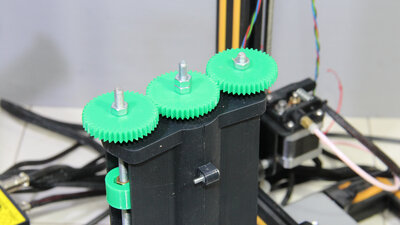

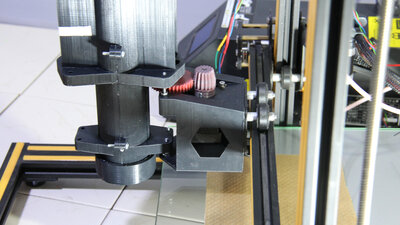

In contrast to Richards design, the piston of the syringe is not driven by a toothed belt, but by two threaded rods. The threaded rods prevent the piston from moving up again when the extruder motor is switched off - the system is self-locking. Three gears on top of the cartridge ensure that both threaded rods move synchronously and thus press the piston down evenly.

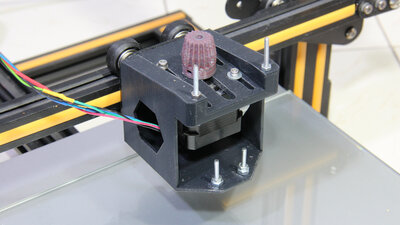

On the bottom there is a fourth gear, which fits on the pinion of the extruder motor as soon as the cartridge falls down along the four screws on the X-axis bracket.

The extruder motor mount replaces the hotend of the CR10S.

A plug with reverse polarity protection enables the printer to be quickly restored at any time and the motor of the Bowden extruder to be reconnected. A piece of filament in the sensor prevents it from being triggered.

With the cartridge you can use syringes with a capacity of up to 100ml. In principle, there is: the smaller the diameter of the syringe, the easier it is to control the extrusion process, since less material is moved per mm of piston stroke. Inserts can be printed for syringes with a smaller diameter. If the syringes are shorter than 13cm, an extra cylinder is inserted, so that the piston can be pressed all the way down.

In addition to the printed parts, two M6 threaded rods each 20cm, 4 ball bearings type 626 and some M6 nuts are required for the cartridge. The two nuts that move the syringe piston are made of brass, as the combination of brass on steel has slightly less friction than steel on steel. DownloadThe 3D files, made with OpenSCAD (including *.stl files) are available as Download-Package.Sample printsI created the sample prints with Dough. This consists of two parts flour, one part sugar and enough sunflower oil to give the consistency of a paste that can be squeezed out of a syringe.

Material: Dough Dimensions: 100x93x3mm Nozzle: 2.0mm Layer height: 1.5mm Extrusion width: 1.5mm

Material: Dough Dimensions: 100x93x3mm Nozzle: 2.0mm Layer height: 1.5mm Extrusion width: 1.5mm

Material: Dough Dimensions: 100x93x3mm Nozzle: 2.0mm Layer height: 1.5mm Extrusion width: 1.5mm

Material: Dough Dimensions: 100x93x3mm Nozzle: 2.0mm Layer height: 1.5mm Extrusion width: 1.5mm <<< Extruder V6.1 + V6.2 Lunar eclipse 2015 >>> News The Project Technology RoboSpatium Contribute Subject index Archives Download Responses Games Links Gadgets Contact Imprint |

|

|