|

|

|

|

News The Project Technology RoboSpatium Contribute Subject index Download Responses Games Gadgets Contact <<< Extruder V5.5 Extruder V6.1 + V6.2 >>> Direct granules extruder V6.0: Teflon insertThe video about Direct Granules Extruder V6.0.The rocky road to a new version

The version jump from the Extruder V5.5 described in the previous chapter to V6.0 was a lengthy, time-consuming process. When experimenting, the rule is: only change one parameter at a time, which, when testing hardware, meant I had to create a looooong number of extruder tubes - only a portion of which are shown here. Extruder V6.0 in detail

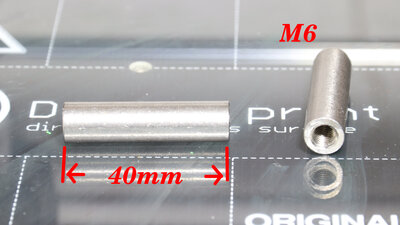

The starting part is an M6 threaded sleeve made of stainless steel. Stainless steel has lower thermal conductivity than regular steel, which is advantageous for low heat flow from the hot end to the cold end.

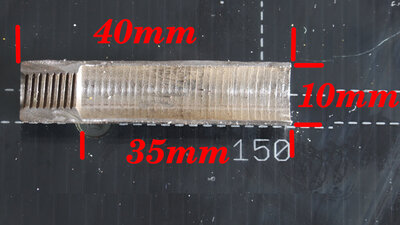

The disadvantage, however, is the higher hardness of the material when machining with my cheap lathe. When drilling the internal thread, grooves are created in a radial direction - it makes no significant difference whether I drill directly to the final diameter or proceed in stages.

The solution was to cut about a quarter of a Teflon tube with a 10mm outer diameter and 8mm inner diameter. When this tube is compressed and glued into the 8.5mm hole, a gap of about 2-3mm remains. This gap ensures that the plastic's radial movement is slowed, while friction in the axial direction of the tube remains sufficiently small. The Teflon tube protrudes about 5mm at the upper end and must not be cut flush!

The internal thread is drilled 35mm deep using an 8.5mm drill bit. Stainless steel can be machined with cobalt-alloyed drill bits. Extruderschraube

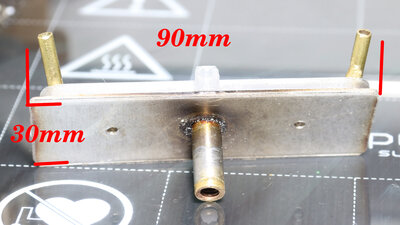

The wood screw used has a 6mm diameter on the outside of the thread. The core diameter of the thread is 4mm. The pitch is 2.5mm. A piece of an M8 brass nut is soldered on top. An M8 nut fits into the gearbox adapter.

The extruder tube is brazed to a strip of stainless steel sheet measuring 90x30x2mm using silver solder.

A piece of 10mm brass rod is attached to the top of the screw as a stirrer. DownloadThe 3D files and the extruder dimensions are available as download package.Examples

Benchy 300% Dimensions: 180x93x144mm Layer height: 0.2mm Extrusion width: 0.5mm Print speed: 120mm/s at acceleration of 10000mm/s2 Print time: 9h The heavy print head causes noticeable ghosting, but the extruder consistently handled the high material throughput.

Makey Layer thickness: 0.2mm Extrusion width: 0.5mm These robots, called "Makey" are printed from a single piece, with internal joints, and all hinges move once removed from the print bed. <<< Extruder V5.5 Extruder V6.1 + V6.2 >>> News The Project Technology RoboSpatium Contribute Subject index Archives Download Responses Games Links Gadgets Contact Imprint |

|

|