|

|

|

|

News The Project Technology RoboSpatium Contribute Subject index Download Responses Games Gadgets Contact <<< EDM: Welding inverter CNC (1) Spot welder >>> Spark erosion with a welding inverter, part 2The video about spark erosion with a welding inverterImprovements

In comparison to the previous chapter I implemented a couple of improvements.

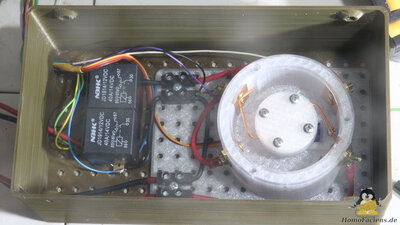

The most important change is that the electrode now rotates, driven by another stepper motor.

The simplest drill chuck proved to be the one with the best runout: Two small 3D-printed parts center the electrode inside an 8mm diameter brass tube. Two M3 screws hold the electrode in position and direct the current toward the workpiece.

The new pump comes from a car's windshield washer system. A simple piece of foam acts as a filter, which has proven surprisingly effective in operation.

Improvements include a microservo-operated switch that allows the electrode to be used either for eroding or for measuring. The polarity between the workpiece and the electrode can be changed using two 12V 40A relays.

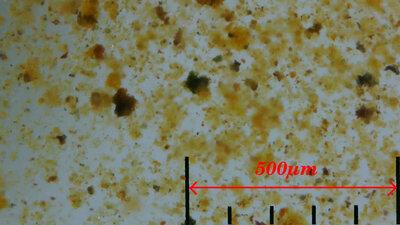

View through the microscope on the particles in the rinse water. Examples

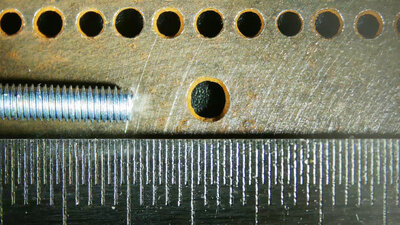

Drilling and marking holes in 3mm stainless steel.

Sieve from 0.75mm steel. Build instructionsStill there is something to be done on this machine before publishing a profound build instruction. Especially the electronics needs major changes. If you would like to support me financially in the further development work on this and other open source machines, in addition to more information and the build instructions, there is also a donate button on my pages. Thank you to all the great people who have already used it to send me an Obol!<<< EDM: Welding inverter CNC (1) Spot welder >>> News The Project Technology RoboSpatium Contribute Subject index Archives Download Responses Games Links Gadgets Contact Imprint |

|

|