|

|

|

|

News The Project Technology RoboSpatium Contribute Subject index Download Responses Games Gadgets Contact <<< Direct granules extruder V3 Direct granules extruder V4.1 >>> Direct granules extruder version 4The video about Extruder V4.Test print with recycled PLA, uncut.About Extruder V4

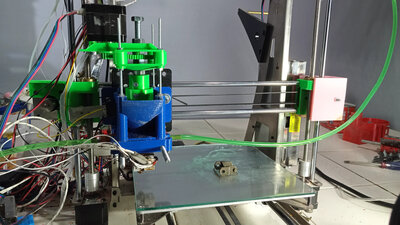

With version 4 I tried to test my ideas for an extruder made entirely of metal at it's core. After initial failures, the implementation of water cooling at the cold end made the breakthrough possible. Although the extruder already works very well, there are still some important details missing for a practical printer, which is why I am only publishing a very rough "build instruction" for hobbyists who like to tinker with my ideas. Construction

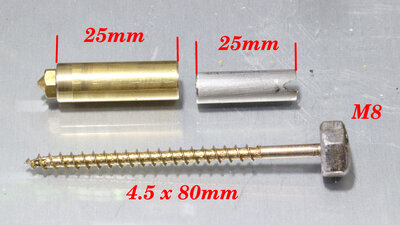

The lower part of the tube is made from 10mm round brass using a lathe. This part is 25mm long The upper part consists of a stainless steel tube with an outer diameter of 8mm and an inner diameter of 6mm. This part is also 25mm long. A wood screw measuring 4.5 x 80mm with an M8 nut soldered to the head acts as auger.

An M6 thread is cut into the brass at the bottom so that standard nozzles can be screwed in.

A 6mm hole goes from top to the thread. There is also an 8mm hole about 2mm deep. This serves as a guide for the 8mm diameter stainless steel tube of the upper part. At the top end, the stainless steel tube has cuts that are approximately 2mm wide and 3mm deep. These help the screw to "grip" the granules and push them into the extruder - there is still room for improvement here too.

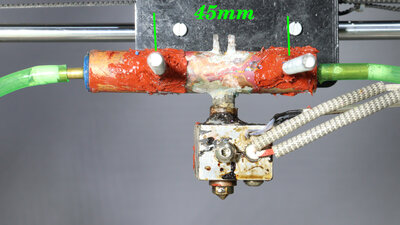

The upper part runs through a piece of copper pipe with a diameter of 15mm and a length of 70mm. The metal parts are brazed, which means they remain permanently connected at temperatures below 500°C.

The extruder is attached to the printer via two pieces of M5 threaded bars.

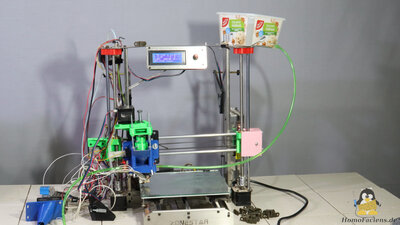

The coldend of the extruder must be kept at temperatures below 40°C. So I sealed the copper pipe and switched to water cooling and that was the breakthrough to a reliably working extruder. The water cooling is driven by gravity. The hose can be clamped using a screw clamp so that the water only drips slowly. Needed partsThe printer I use is a Zonestar QR2, which to my regret is no longer manufactured.The main gear is mounted on one piece of an M8 threaded rod with two ball bearings type 608 (8x22x7mm). The hopper is attached with M3 threaded rods (4x 200mm). It is attached to the printer using M5 threaded rods (2x 200mm) A lot of M3x16 screws and M3 nuts are also required. The parts should be printed from PET-G. DownloadI created the 3D files with openSCAD. Both the scad file and the stl files are included in the download package.The chain link printed as an example in the video is also available as an OBJ file for download Example print

Track link: Layer height: 0.2mm Nozzle: 0.4mm Print time: 17min Size: 27x25x12mm Material: Recycled PLA <<< Direct granules extruder V3 Direct granules extruder V4.1 >>> News The Project Technology RoboSpatium Contribute Subject index Archives Download Responses Games Links Gadgets Contact Imprint |

|

|